This is a story of one of the projects we have in the lab. It's an experiment and proof of concept. At this point, we aren't committed to creating a product out of this idea. I'm interested in hearing comments you have about it. We presented a paper about it at AutoTestCon a couple of years ago, and I've demo'd the system to a few key customers.

We have customers who have aging test systems, often based on discontinued GPIB instrumentation. There's often no money to update the overall system. Changing out hardware usually implies modifying the software. The software has often gone through some sort of validation process, so any change to the software can become extremely expensive since it would have to be revalidated.

If an instrument fails, the engineers can either hope for vast amounts of money to rebuild the entire test system with modern hardware, or they can try to repair or replace the old equipment. eBay has become a useful tool for finding old instrumentation.

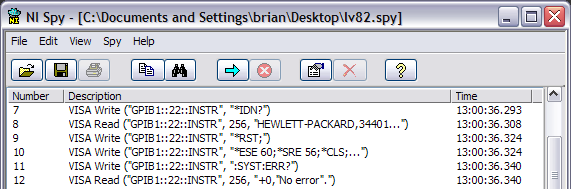

So our experiment was to take a modern PXI-based measurement system, and make it pretend to be a GPIB instrument. The PXI controller listens for commands on its built-in GPIB interface. We wrote software that parses those commands and maps them to specific LabVIEW VIs running on the controller. Responses are sent back out the GPIB interface.

I imposed a couple of requirements to make things interesting...

- The system had to be as generic as possible. I didn't want to encode any traits of a DMM or Scope or Spectrum Analyzer into the system. For this, we created an XML schema to define the commands that the system understands, as well as how those commands map to VI calls.

- The system had to be extensible by end users using LabVIEW. We aren't making turnkey instrument replacements; we're making a framework for end users. This lets end users (or system integrators) control the fidelity of their emulation. This might range from deriving custom measurements, to slowing down measurements to more accurately emulate legacy instrumentation.

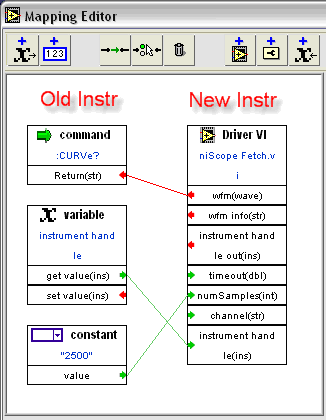

We came up with an editor to map commands to VIs. With this editor, you don't have to edit the XML directly. Here's a screenshot showing the CURVe? command for a scope...

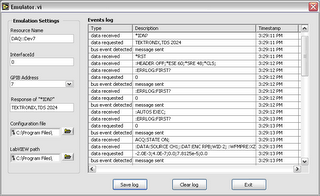

When the system is running, the display shows a log of all the commands and responses... (Click to enlarge.)

So where are we now? The system works. It's got some rough edges—mostly things that could be easier. As a proof of concept, our engineers did a wonderful job. It's pretty cool to watch this system in action. But, we're waiting for customers to tell us whether and how we should take the idea further.

The biggest piece of feedback so far is that customers wish it were more "turnkey". It's one thing to emulate the command set of an aging instrument. It's another to faithfully emulate measurements. Our PXI-4070 6 1/2 digit DMM is faster and more accurate than many older box-based 6 1/2 digit DMMs. But you usually would rather have equivalent accuracy, not more accuracy. A faster and more accurate measurement could be a problem in some test systems.

I also want to point out that more turnkey solutions are available. WinSoft (a National Instruments Alliance Partner and Agilent Channel Partner) has a product called WinSoft Instrument System Emulator (WISE). I do not have experience with their products, but I know they have years of real-world experience.

If you've got thoughts on our instrument emulation project, please let me know.

Read more of this article...

This is an Agave Havardiana in the Chisos Basin in the central part of the park. (Image Copyright © 2006 Brian H. Powell. All Rights Reserved.)

This is an Agave Havardiana in the Chisos Basin in the central part of the park. (Image Copyright © 2006 Brian H. Powell. All Rights Reserved.)