A comment on an older post asked about LXI. What is LXI, and what does it mean for LabVIEW users?

LXI stands for LAN Extensions for Instrumentation. The name follows in the fine tradition of VXI (VME Extensions for Instrumentation) and PXI (PCI Extensions for Instrumentation). There's a standards body that defines the LXI standard, which specifies what an instrument has to satisfy in order to get an LXI logo on its front panel.

LXI defines three classes of conformance. Class C is the simplest—basically the instrument has to have an Ethernet port and be able to serve up a web page. (There are many more operational details in the spec, such as specifying how devices get an IP address.) Class B adds IEEE-1588 timing and synchronization (see below). Class A adds a Wired Trigger Bus, which provides more precise timing and synchronization than you can get over Ethernet. (Again, I'm simplifying to what most users need to know. There are many operational details required for true conformance. Read the specs.)

Many Class C devices are just repackaged versions of older GPIB designs, adding Ethernet as a new way to talk to your DMM or Oscilloscope. (Many devices include connectors for Ethernet, GPIB, and USB in one package. Ethernet gives you distance. USB gives you plug and play simplicity. And as one test engineer put it, "GPIB just works".

Class A and B devices add complexity (and cost) in order to get better timing and synchronization. Most of the LXI-compliant devices available now are class C.

To be clear, National Instruments is not a member of the LXI Consortium. But I do pay attention to it. I've read the standard. I've been to some of the meetings. I've programmed a test system of LXI devices. I have firsthand experience with LXI.

LXI — Yet Another Way To Build a Test System

One of the many marketing messages behind LXI is that it is the "successor to GPIB". I think a more realistic message is "yet another way to build a test system". LAN-based instrumentation systems have their pros and cons. There are some things that are better than GPIB. There are some things that are worse.

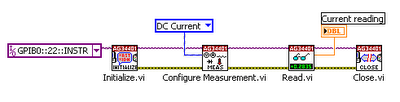

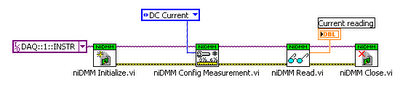

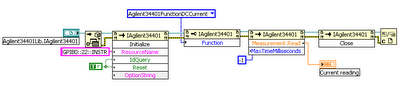

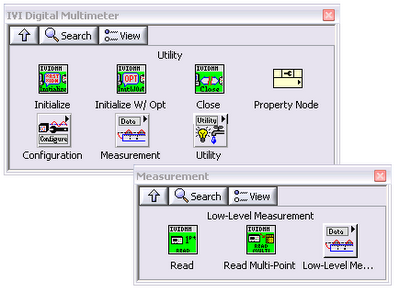

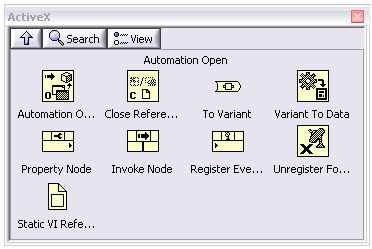

LabVIEW is the best way to build a test system, LXI included. (Maybe I'm a bit biased. ;-) As T&M World editor Rick Nelson said recently in his LXI blog, the reality is that a lot of test systems are going to contain a variety of bus technologies. The purpose of VISA was to make it easier to incorporate new bus technologies into existing test systems. Work was done in the mid-1990's to produce the VXI-11 standard for Ethernet-based instrumentation. LabVIEW and VISA have been supporting LAN-based devices for years.

When is LXI right for you?

The one clear advantage that Ethernet has over most other bus technologies is distance. You can distribute instrumentation across the globe and talk to those devices over the internet. However, the further you distribute nodes on Ethernet, the more you run into issues with security, reliability, and timing and synchronization.

The LXI Consortium realizes that timing and synchronization are hard to handle, since you have less control over how packets are propagated through the network. That's why LXI adopted the IEEE-1588 standard for precision timing over Ethernet.

With IEEE-1588, you can trigger across a network with an accuracy of less than a microsecond. This level of accuracy has some constraints. You can only get this accuracy if you're connected through a simple network hub. Most corporate networks (and many home networks) use a network switch or router. These devices slow packet transfer by a few microseconds. It's imperceptible when viewing web pages, but these delays could cause problems in a high-end RF test system. NI has a PCI-1588 Ethernet controller. We publish 1588 synchronization specs for different network configurations in our PCI-1588 data sheet.

So, while LAN-based instrumentation is great for distributing systems across the miles, IEEE-1588 synchronization works best in small closed networks. (Note: IEEE-1588 is currently being revised to have higher accuracy. It appears the new version will not be backwards compatible with the current version.)

LXI—Simpler Cabling?

Here's an example of why no one pays me to build test systems...

This shows the back of a test system built mostly out of LXI class A devices. Ethernet cables, Wired Trigger Bus cables, RF signal cables, power cables. Before it goes anywhere, we'll clean all this up. My point is that LXI doesn't necessarily simplify cabling.

GPIB allows us to daisy-chain devices together. Ethernet, on the other hand, requires that all the cables go back to a central network hub. (In my case, a $4000 IEEE 1588 network hub.)

"Hello. It's your IT department. What are you doing to our network?"

One choice to be made in constructing an Ethernet-based test system is whether to use a private network (i.e., no connection to the outside world), or whether to hook it up to your corporate network. In some companies, plugging an LXI device into the corporate network will evoke a response similar to calling the fire department. "Bandit in cubicle 3A101! What is that device?!?! What viruses is it spreading?! Security breach! Lock the doors!" Fortunately, I don't work in such a company. But many of the more expensive new measurement instruments run some form of Microsoft Windows, and our IT department is definitely concerned about having those systems up-to-date with patches and anti-virus software.

Once you get past the IT issues, there are some practical concerns. On a corporate network, you don't always control the traffic going over your part of the network. This affects timing and synchronization, to be sure. But more practically, I've seen LXI test systems interrupted in the middle of measurement because someone decided to probe the network searching for LXI devices. The LXI Consortium recognizes the problem and has begun working on a solution (called "resource locking"), which will eventually make it into the specs.

Issues like these push engineers to use a private network, but then you'll start to miss your IT department. You'll have to provide your own DHCP server (or do without and configure static IP addresses, like I did). You'll have to provide your own DNS server (or do without, and refer to devices with IP addresses the way I did: "TCPIP::192.168.200.2::INSTR").

Summary

Key takeaways...

- LXI — Yet another way to build a test system

- LXI — Yes, you can talk to it from LabVIEW

I have a lot more I could say about LXI. Let me know what you want to hear.

Read more of this article...